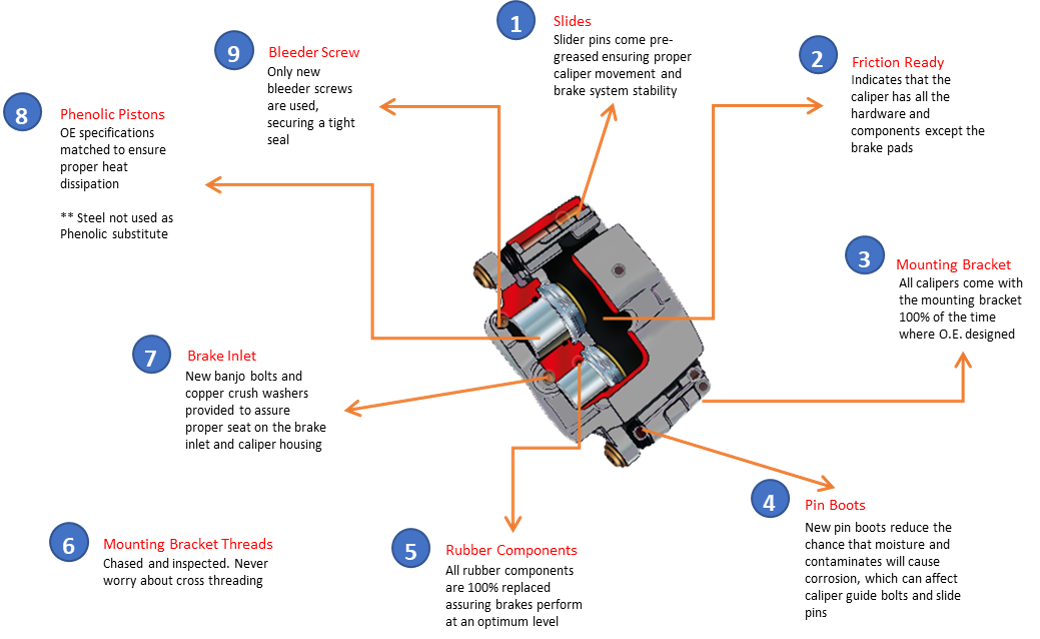

- 100% core inspection and qualification with a proprietary core receiving process.

- The disassembly process ensures maximum component salvage and integrity.

- A 100% component inspection and testing process ensures well-defined acceptance criteria before assembly.

- 100% End-of-Line test for pistons displacement, force, and delta between pistons forces. Acceptance criteria and specs are developed by benchmarking OE samples.

- 100% in-process fitment inspection, utilizing OE samples geometrical data via certified inspection gauges.

- All wear-prone components such as elastomers, rubber, seals, and fasteners are subject to mandatory replacement with new ones.

- Corrosion protected by Premium Quality E-Coat.

- Utilization of internally developed best-in-class cleaning

Coverage of All Applications

1.Choice of Friction (WD & Tech)

2.Ready for Installation (Tech)

3.No Surprises (WD & Tech)

4.Quality Assured (WD & Tech)

5.16 SKUS Available for this program

Last updated: Monday, 26 August 2024 04:36 PM